|

Home Machine Tool Archive Machine-tools Sale & Wanted A.L.1, A.L.2, A.L.3, A.L.Y.1, A.L.Y.2 & A.L.Y.3 |

||

|

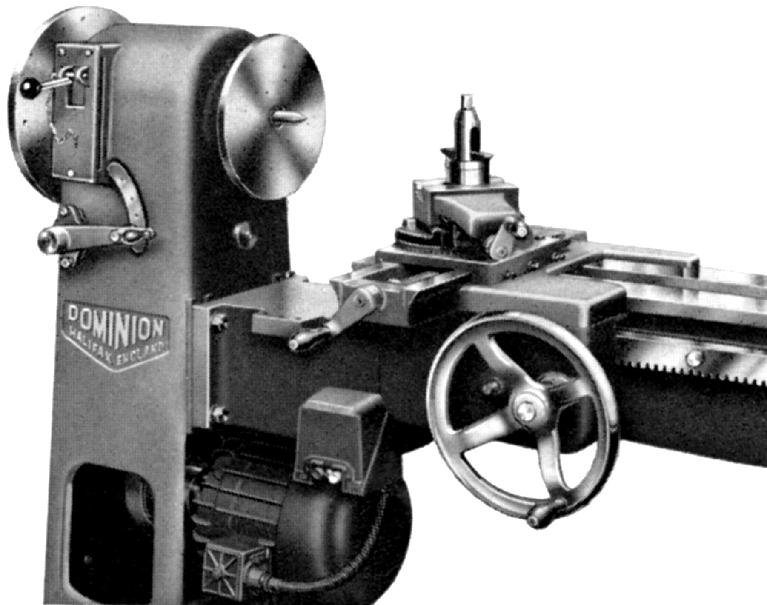

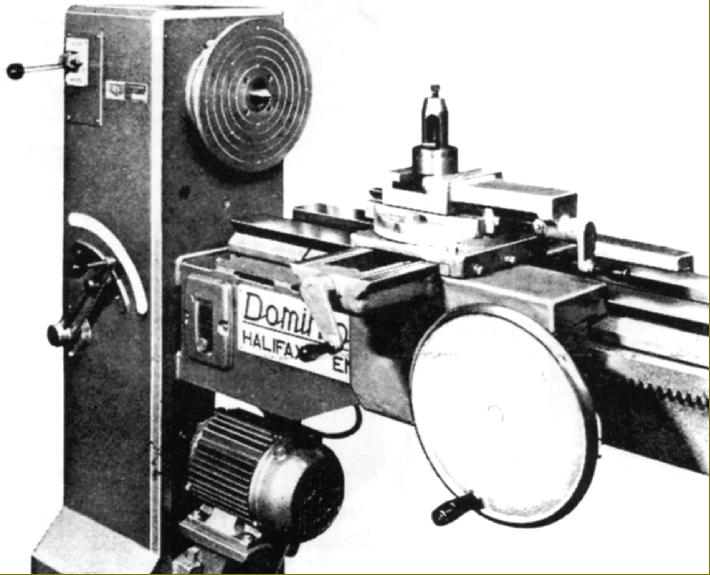

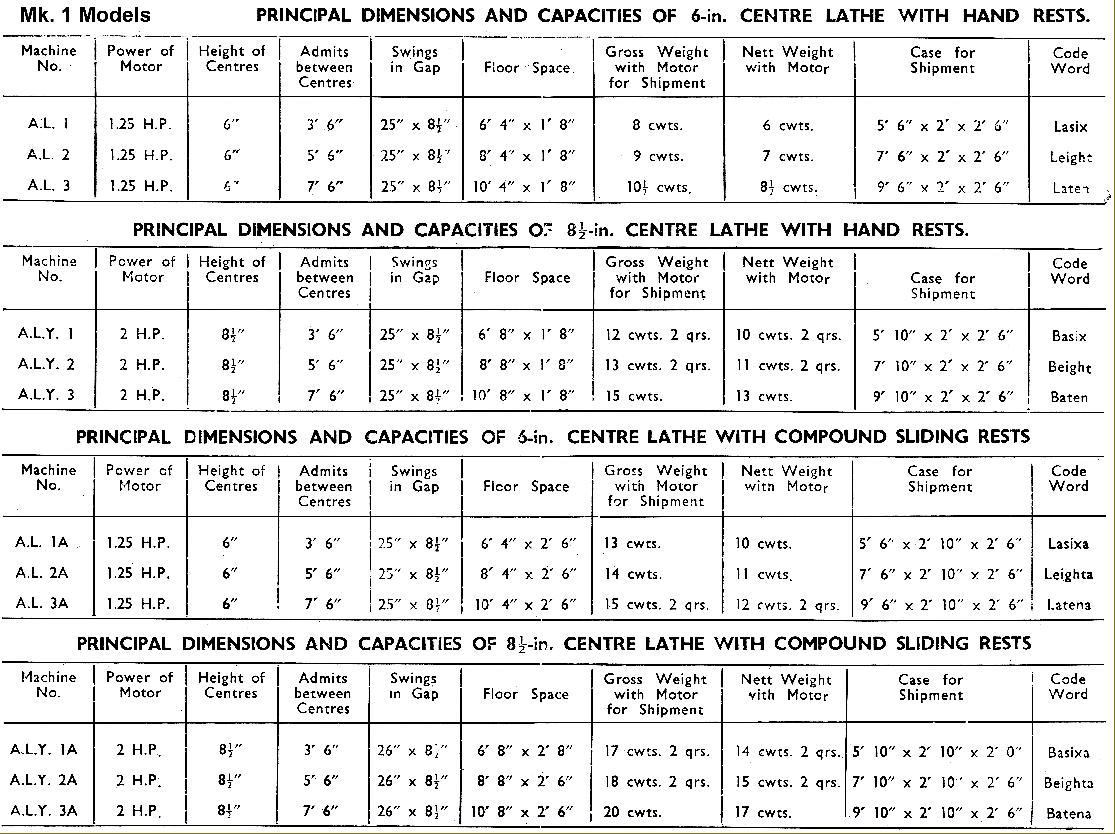

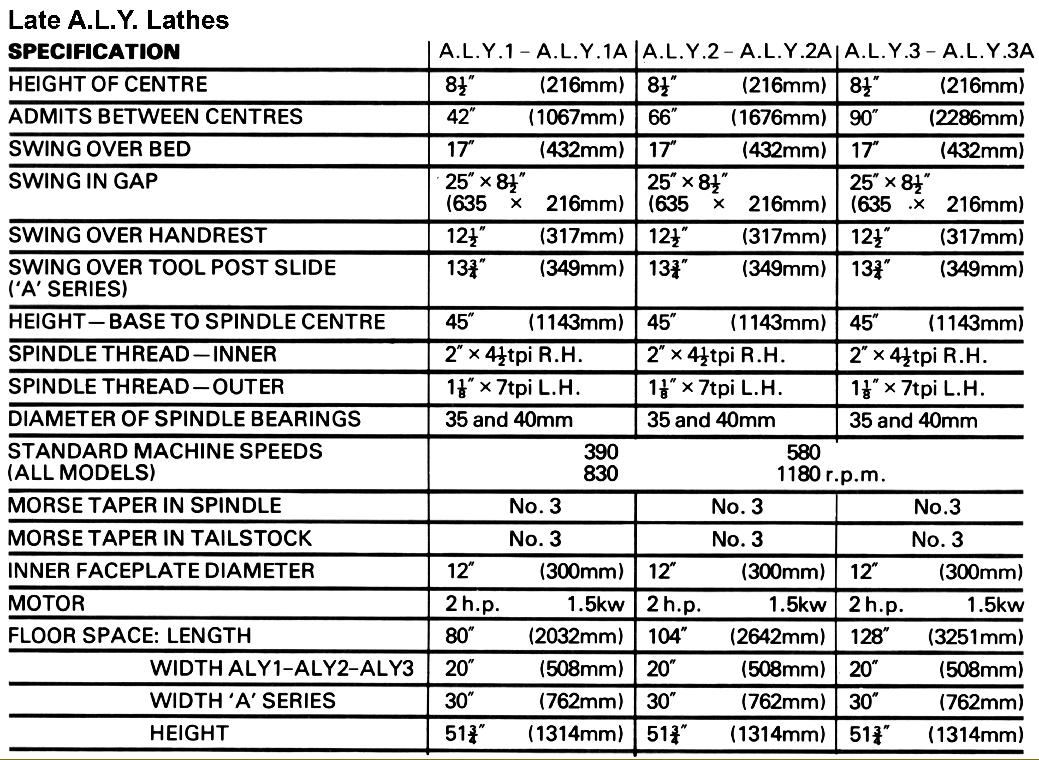

Offered originally as the 6-inch centre height "A.L.1", "A.L.2" and "A.L.3" and 8-inch "A.L.Y.1", "A.L.Y.2" and "A.L.Y.3" (the former eventually being dropped), this range of heavy, all cast-iron Dominion lathes gained an "A" suffix to their model type when fitted with a very robust rack-feed carriage and compound slide rest. The top slide could be swivelled through 360°, was graduated 45° each side of central and carried an "American" style toolpost. Although heavy-duty, the slide rest assembly was basic, with the feed screws lacking micrometer dials and turned by antique-looking crank handles. |

|

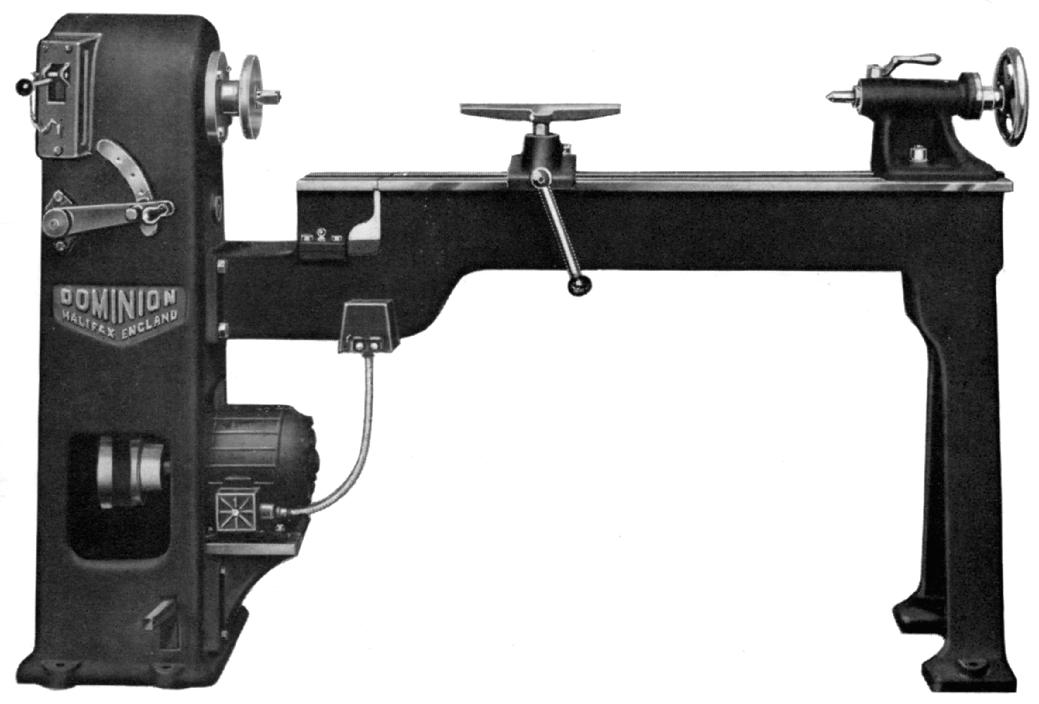

Dominion Mk. 1 A.L.Y. 1, 2 and 3 - respectively 38, 66 and 90 inches (1050, 1650 and 2250 mm) between centres. The model illustrated is a standard machine, supplied without an extended spindle for outboard bowl turning |

|

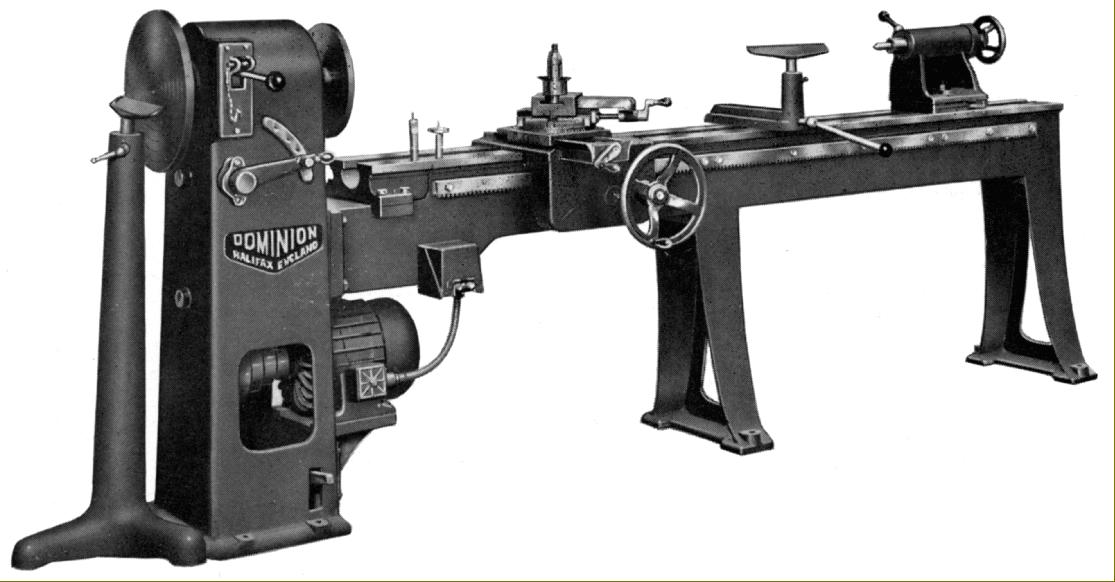

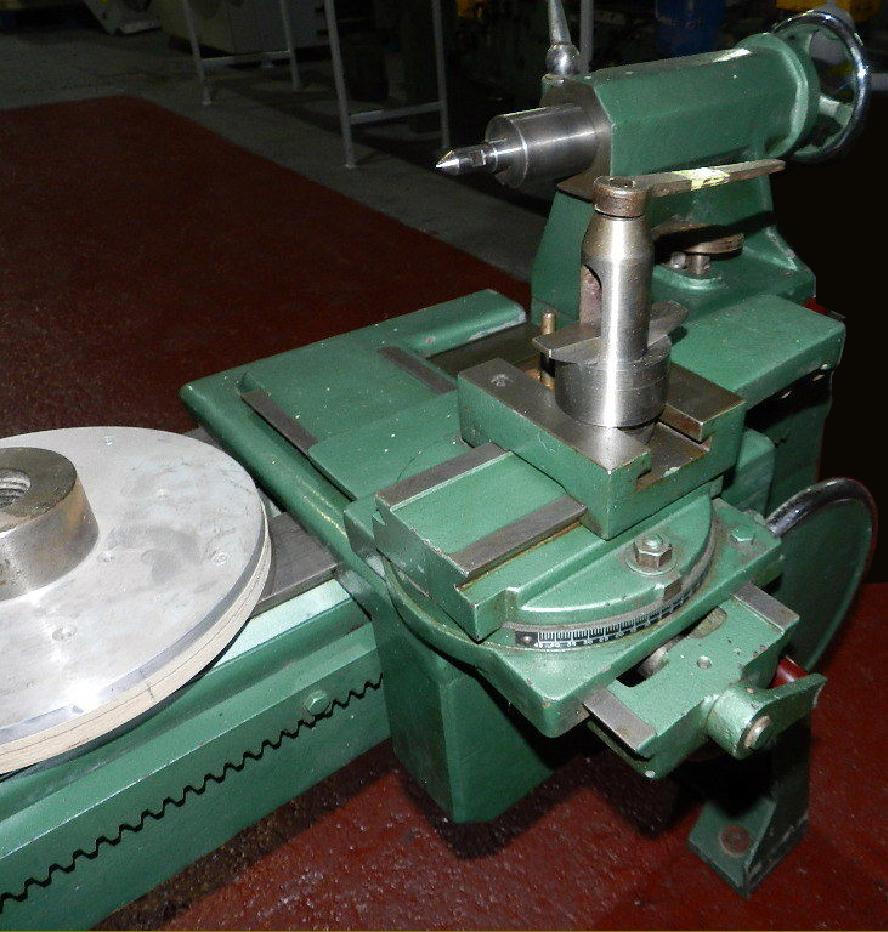

Early Dominion Mk. 1 long-bed A.L.Y. 3A with 90 inches (2250 mm) between centres and fitted with a central bed support , a screw-feed compound slide rest, extended spindle to the left and a free-standing bowl-turning rest. |

|

Dominion Mk. 1 A.L.(Y.) fitted with a very robust rack-feed carriage and compound slide rest carried the suffix "A". The slide rest screws lacked micrometer dial and were turned by crank handles |

|

|

|

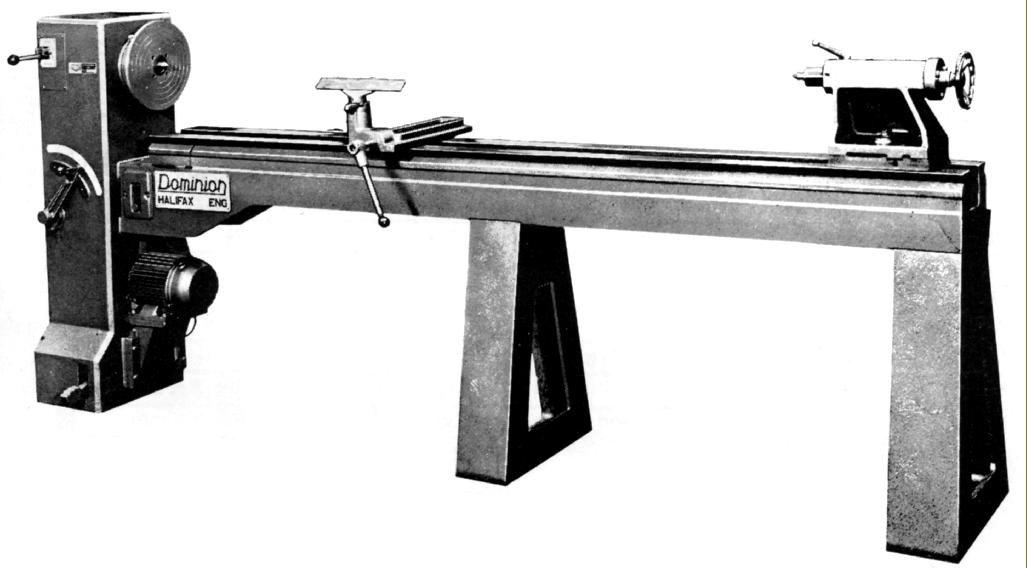

Even though the overall appearance was more modern, the A.L.Y. lathes retained the compound slide rest from the earlier models |

|

|

|

|

||

|

|

|

Picture left and below from Brian at finewoodcaver.com, a craftsman involved in high-quality carving and other special commissions. |

||

|

|

|

A.L.1, A.L.2, A.L.3, A.L.Y.1, A.L.Y.2 & A.L.Y.3 Home Machine Tool Archive Machine-tools Sale & Wanted |

||