|

Home Machine Tool Archive Machine-tools Sale & Wanted Milling Machine |

||

|

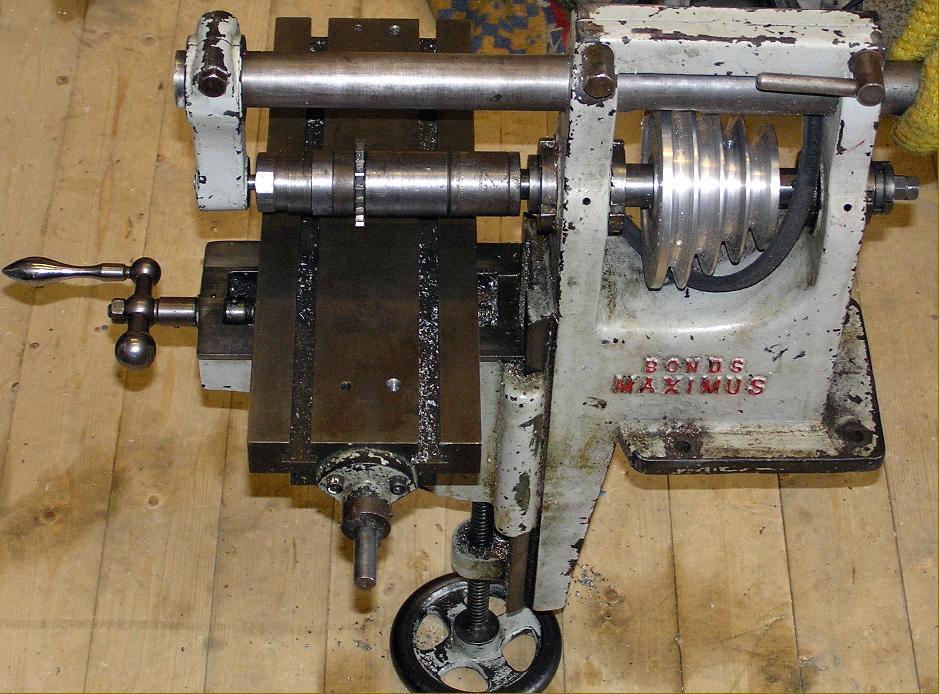

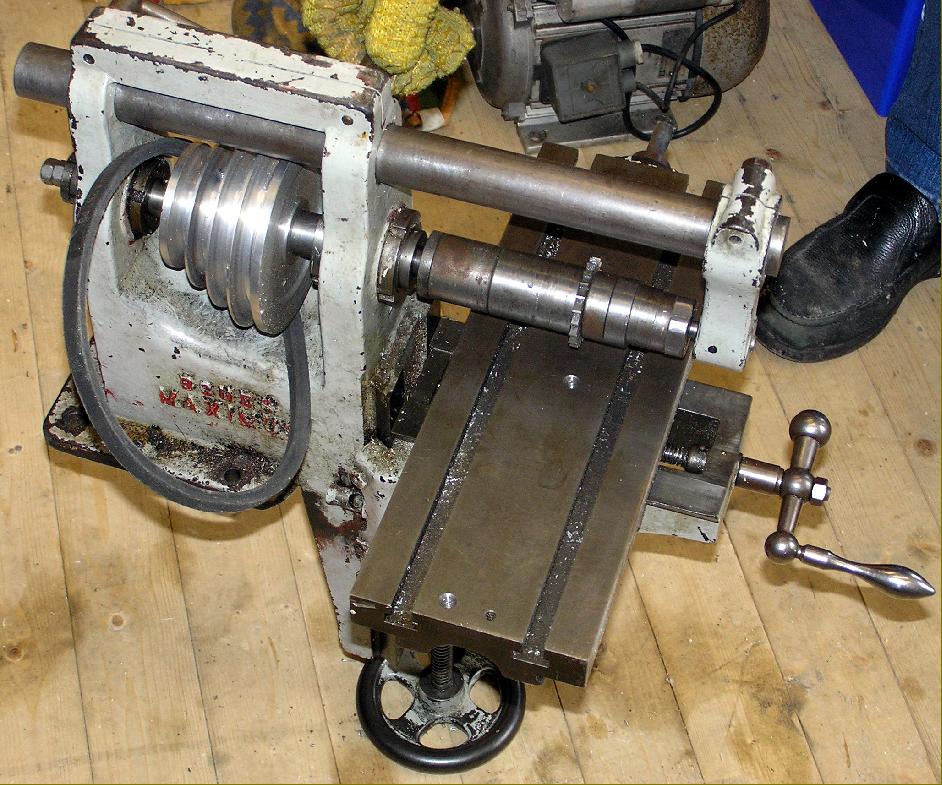

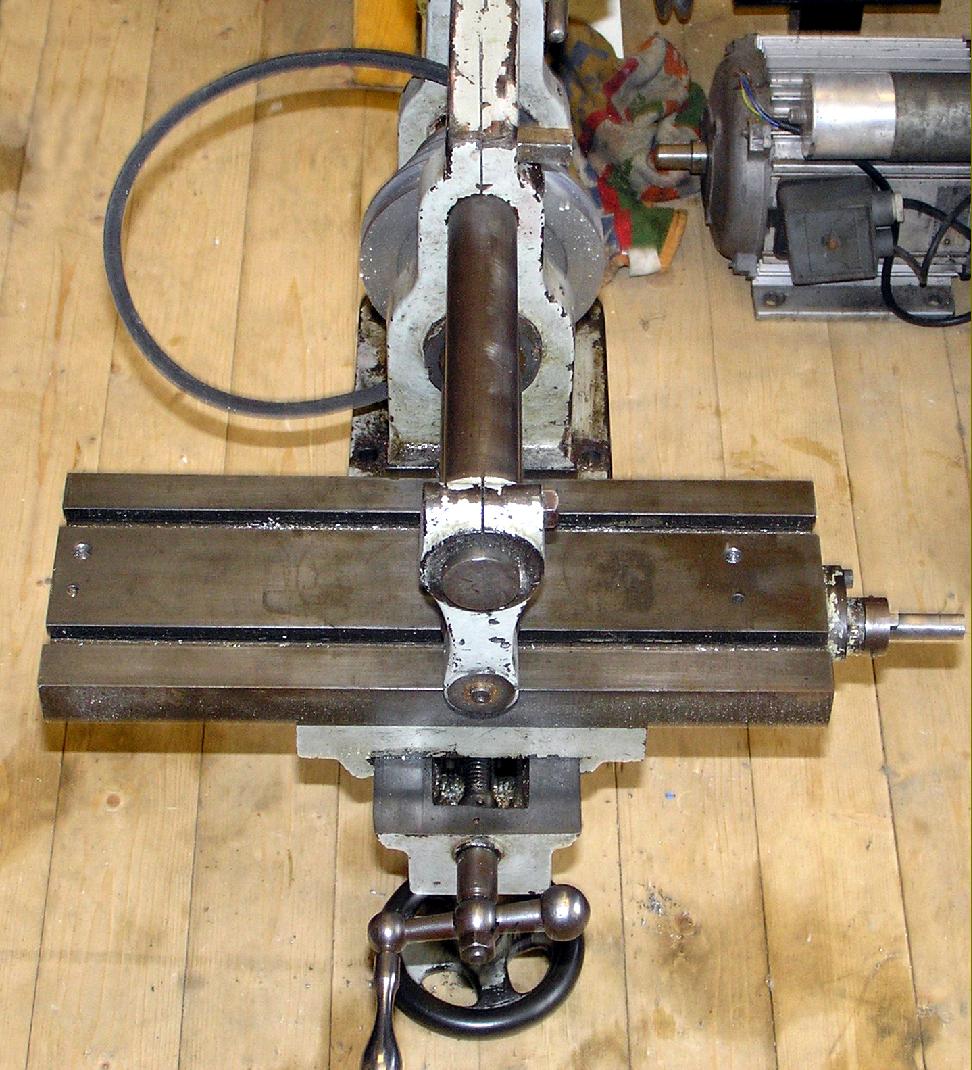

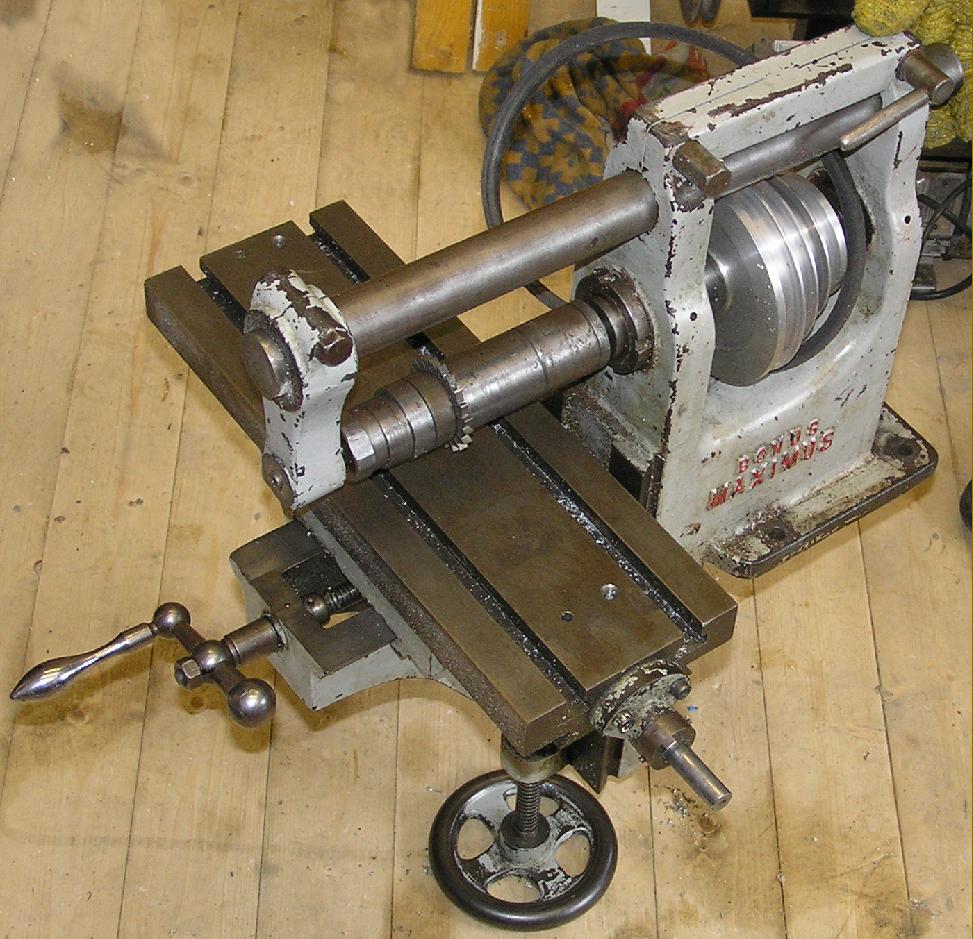

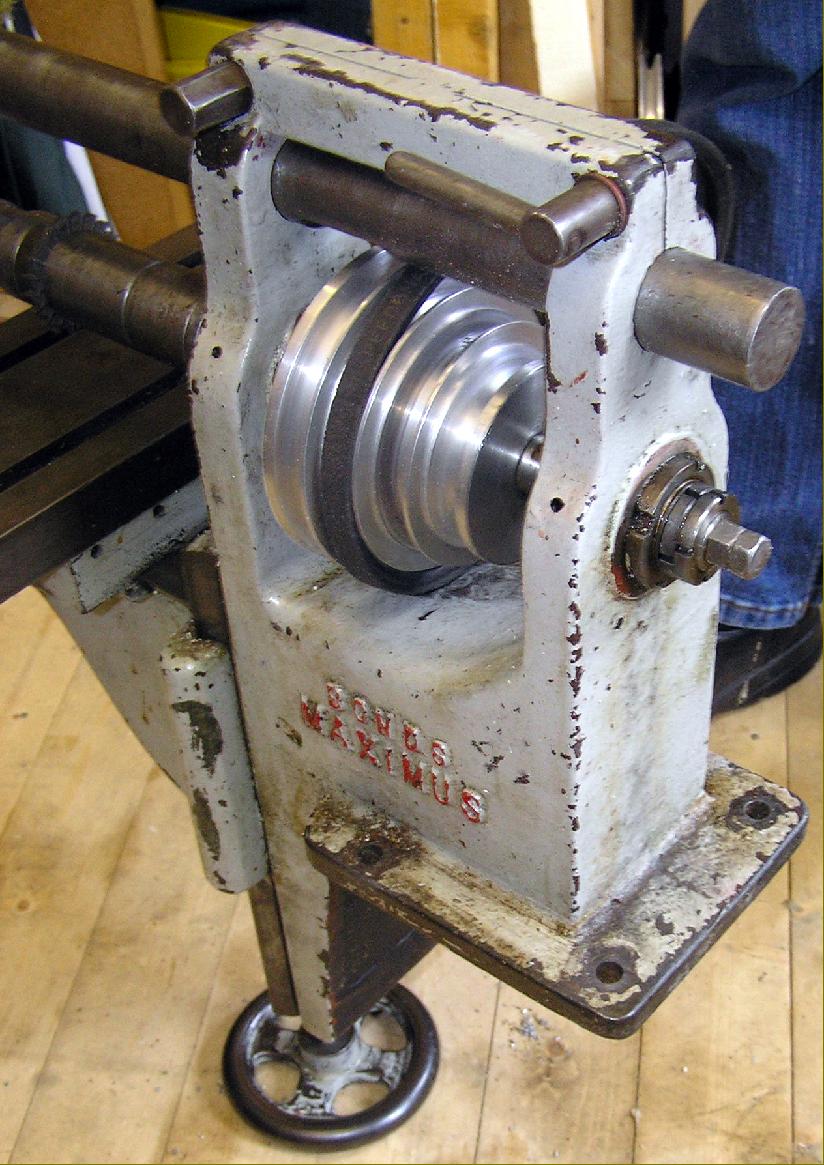

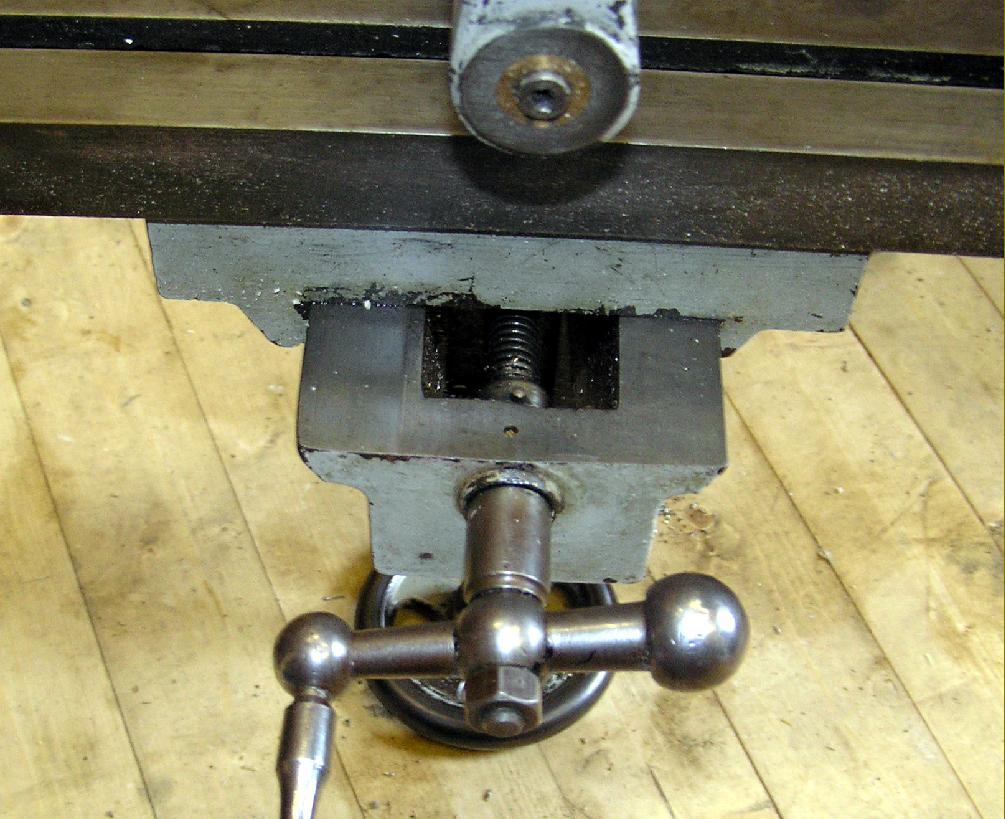

A very similar machine to at least one of those offered by fellow tool and machinery dealers Pools of Nottingham, the Bonds horizontal miller would have been subcontracted to one or more of the many small engineering companies in the area to the north and east of Derby. A simple, 108 lb device intended for use by model engineers, it was designed to sit on the front edge of a work bench so that the vertical feed screw for the knee did not have to pass downwards though the bench top. Even so, it was still necessary to make a small cut in the edge of the bench to accommodate a stiffening rib on the back of the knee casting. The table size appears to have varied, with some being a useful 14 inches long and 5.125 inches wide, whilst others were the same length but rather narrower at just 3.37-inches. Travel was between 9 and 10.5 inches longitudinally, a traverse of 2.25 to 4 inches and a vertical rise and fall of 7 inches. None of the table's feed screws was fitted with a micrometer collar - though both the X and Y axis could be locked |

|

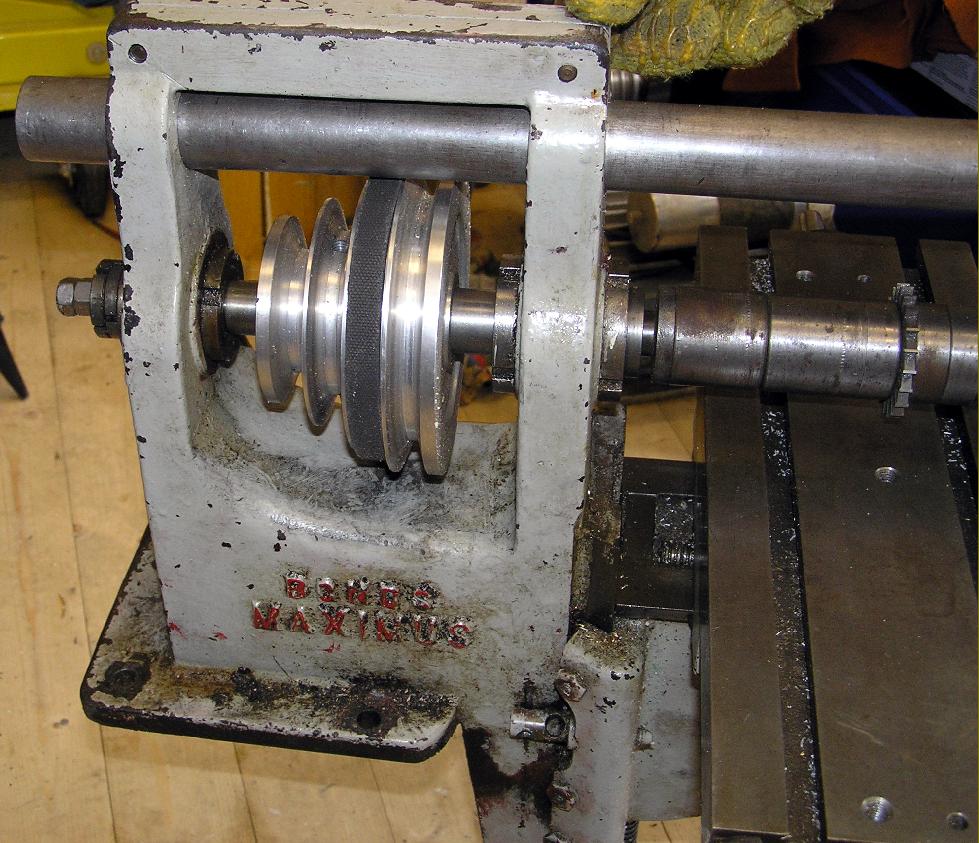

The original 3-step flat-belt pulley has been replaced by a Picador V-belt type - otherwise this Maximus milling machine is completely original. As shown the cutter-holding |

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted Milling Machine |

||