|

One of a number of combined drilling and milling machines made by Aciera, and intended for precision drilling and tapping in both toolrooms and production settings, the Types 22 and 23 were described by the Company as both "co-ordinate drilling, tapping and boring machines" and also, when fitted with a compound, T-slotted table, as being of the "semi jib-boring type". Both early and late models were produced, the former recognisable by its rounded styling and the latter by a more modern, angular appearance (the early versions also lacked a T-slotted foot).

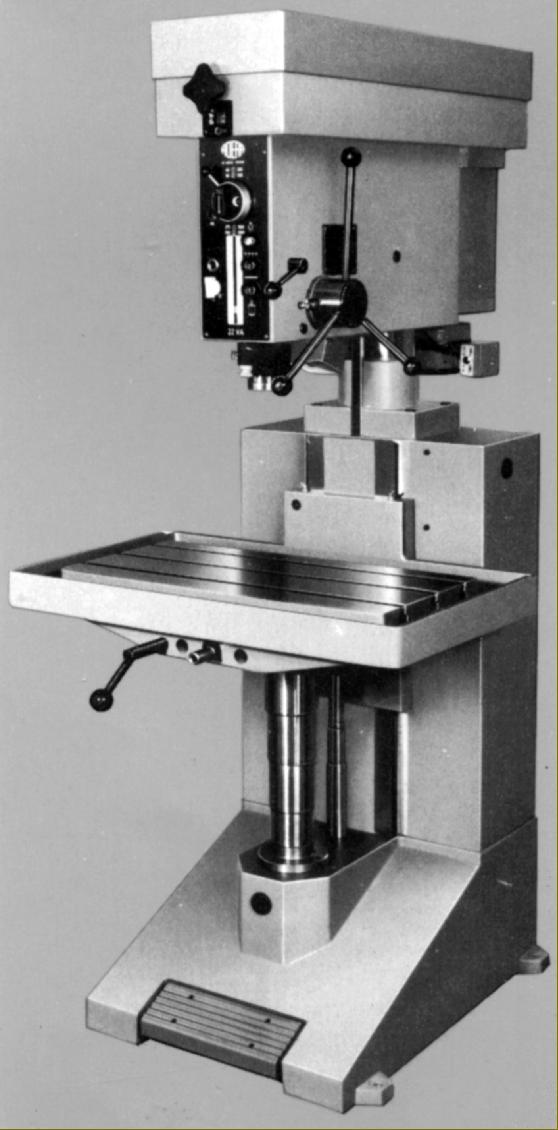

In order to produce as wide a variety of types and sub-types as possible, the makers built machines up from two separate elements - head and base - mixing and matching various kinds of each as needed. Base sections were made with either a full-height, round column and a table elevated by rack-and-pinion gearings or, of heavier construction, with the column as a heavy cast-iron box and the head carried on a round column. The head-carrying column had its supporting base bolted to the main structure while the table was lifted by a milling-machine-type screw - these models being the "semi jib boring" versions type. Heads could be had as either the standard 22V variable-speed type - using mechanical expanding-and-contracting pulleys - or, on all other versions, with the same variable-speed mechanism combined with a reduction gearbox containing hardened and ground gears running in an oil bath together with various fitting that allowed actions such as tapping or power down-feed boring to be accomplished. Power on all types came from a 2-speed motor flange mounted at the rear of the head - a typical Type 22 had eight spindle speeds marked in fixed positions at: 37, 75, 250, 300, 500, 50, 500, 600, 2000 and 4000 r.p.m.

Running in a combination of high-precision taper roller and angular contact bearings the spindle end was machined to take tools held in special adaptors similar to INT30 but with 3 or 6 indents around the taper. The indents engaged with ball bearings in the female taper of the spindle, locking the tool in position and so making tool changes quick and simple - when the spindle was raised above its normal position and the tool holder fell out. From memory the quill microswitch stopped the motor and engaged the brake to prevent the tool rotating - with the feed lever raised a new holder was inserted and the handle released (the operating manual warned that the spindle should not be rotated without a tool holder due to its special construction ).

Speeds varied according to the particular model (and were not always listed in the technical literature) though a general range for a Type 22 spanned 40 to 560 r.p.m. through the reduction gearing and from 275 to 3600 r.p.m. in direct drive - this coming (seemingly on all versions) from a 2-speed, 3-phase motor flange mounted at the rear of the head.

Head Types V and VA could be equipped with variable-rate automatic spindle power downfeed and withdrawal - the mechanism consisting of either a hydro-pneumatic or hydraulic power unit with advance and retreat caused by the hydraulic cylinder acting on the spindle through rack-and-pinion gearing. On the former, compressed air-supply at 5-6 bar was transformed by two pressure intensifiers to give a hydraulic pressure 4 times higher - this exerting a force on one side or other of the hydraulic piston depending upon the direction selected. The hydraulic power pack consisted of an oil reservoir, pressure pump and the necessary control valves, the drilling cycle being activated or disengaged by 2 push-buttons mounted in a metal box of the left side of the head. Accuracy of drilling depth was obtained by an adjustable stop while a time-delay relay was used to retard the rapid withdrawal of the tool. Spindle travel was 90 mm (3.54") and the adjustable feed rate had a very wide range - able to be set at between 20 and 3000 mm/min (0.79" to 118") - with the automatic withdrawal set at a fixed rate of 4000 mm/min (157").

For production tapping processes, all heads with the reduction gearings could be equipped with an "electrical" tapping accessory, this device appears to have consisted of a motor/gearbox unit that picked up its drive from the bottom of the main motor shaft with actuation by micro-switches at the beginning and end of the quill stroke. In addition a special head, the VG, was offered that contained a built-in, all-mechanical tapping mechanism. The VG head was based on the ordinary variable-speed type (with reduction gearing), and offered speeds from 55 to 720 r.p.m. in low range and from 275 to 3600 r.p.m in direct drive. Tapping speeds could be set at any point in the low-speed range (but not, of course, in the higher) with sensitive operation by friction cones that allowed the all-important automatic reversal.

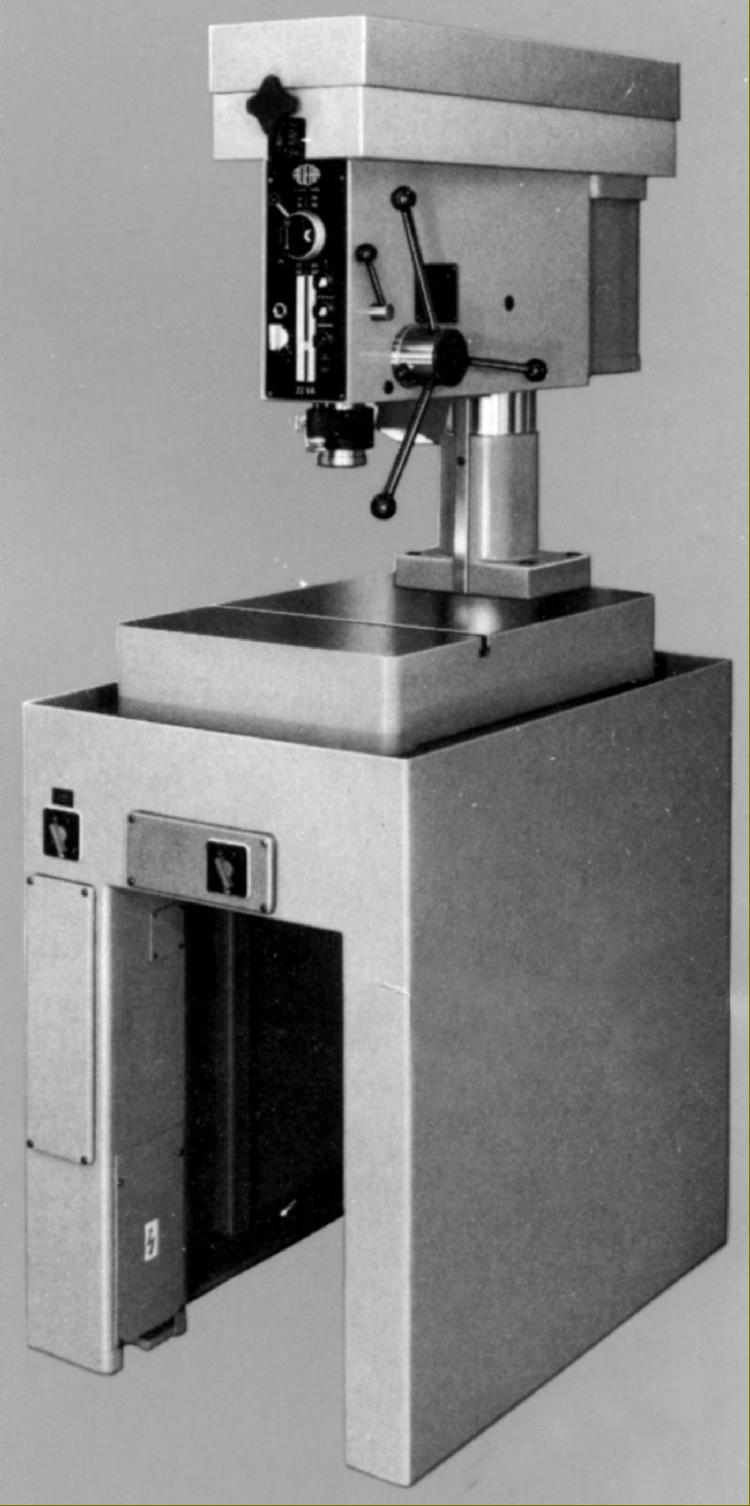

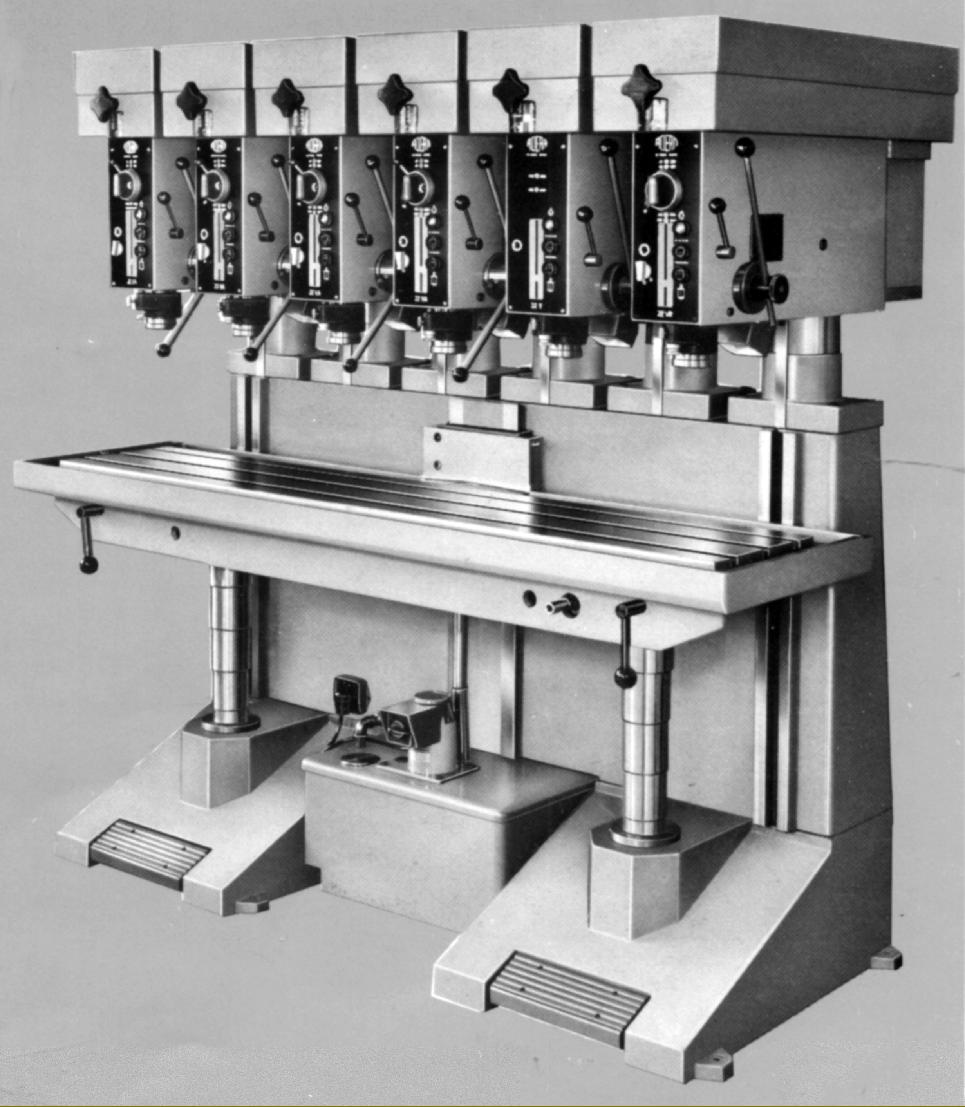

Versions of the Type 22 for both bench and floor-standing were manufactured - though the former consisted of just the round-column single head 22-T1 and double head 22-T2 - with each able to be fitted to a floor stand in welded sheet steel when their model number included a "K" the suffix. When mounted on a cast-iron floor stand an extra two versions were available, the three and four-head Types 22-K3 and 22-K4. Table size on the basic T1 was 510 x 470 mm (20.1" x 18.5") with the all versions of the multi-head machines having the same 510 mm front-to-back width but, of course, as long as needed to accommodate the number of heads fitted.

In an attempt to cover as many requirements as possible, Aciera offered the floor models as two main types in a number of specifications. Most basic of all was the 22C, a version having a full-height round column carried on a heavily-constructed 520 x 600 mm (20.5" x

|

|